- Talalay Latex is Healthy By Design

It is naturally breathable so it dissipates body heat

It is naturally mold and mildew resistant so it may help your sneezing and wheezing

It is naturally dust mite resistant if you have asthma

It is inherently antibacterial and antifungal

It is naturally hypoallergenic so it doesn’t off-gas

It is naturally motion isolating so you will feel less of your partners movement

THE TALALAY PROCESS

Combination of liquid latex, soaps and rubber curing agents are mixed together in a temperature controlled, stainless steel tank to create a batter.

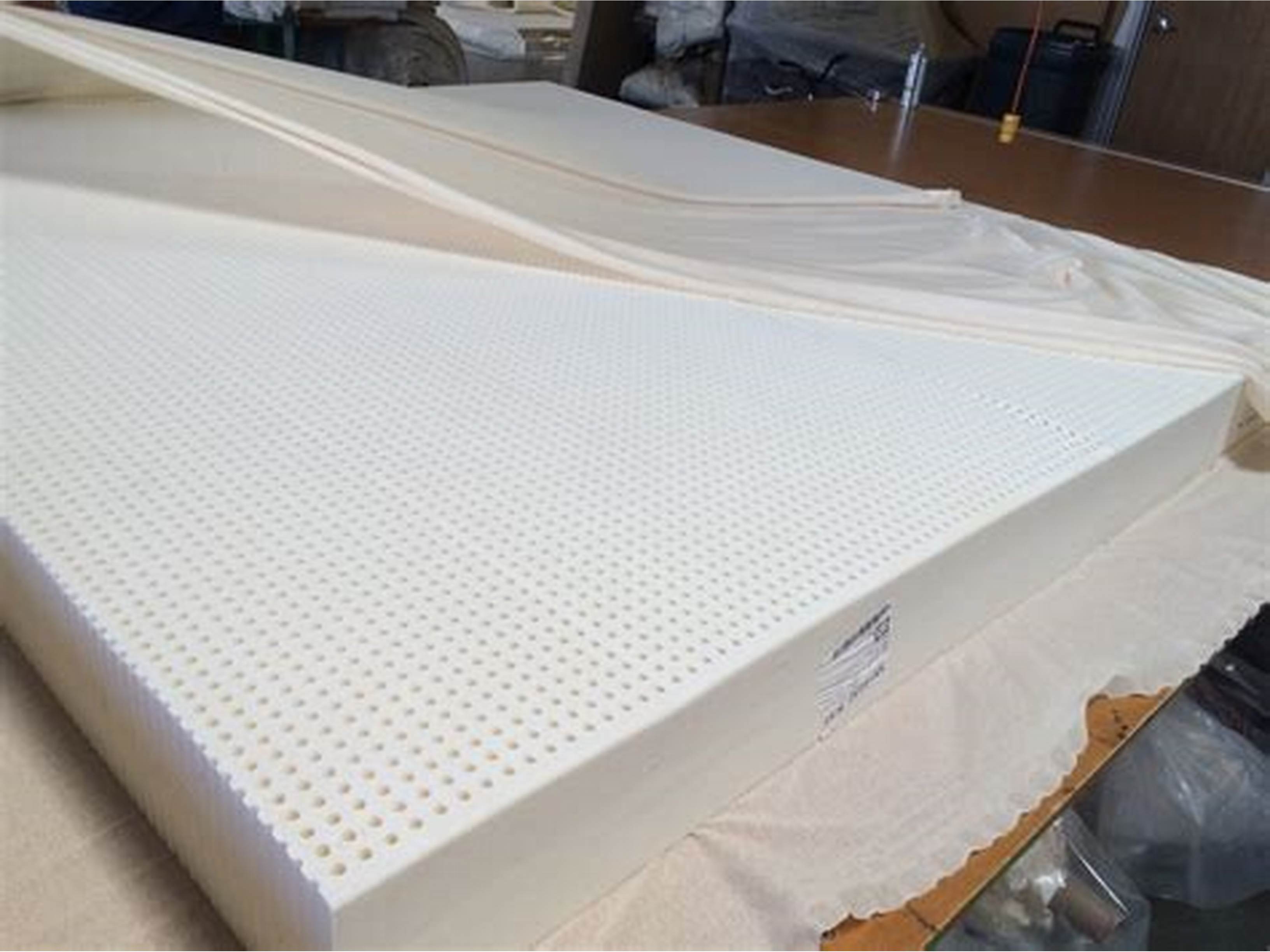

The batter is transferred to the pressroom where it is whipped into a froth and injected into an aluminum pincore mold. The pins create the unique aerated cell structure of our latex.

The mold is sealed and a vacuum is pulled to extract air and completely fill the mold cavity with foam.

The batter is frozen to a temperature of -20 degrees. Freezing is unique to the Talalay process to prevent particles from settling, ensuring a consistent cell structure.

CO2 is added to whip the recipe into a frothy state. Temperatures exceeding 220F-degree are applied to cure the recipe as it is baked into a solid state.

The solid latex is cooled and removed from the mold.

The latex mattress core is removed from the mold and placed on a conveyer belt that brings it through a five-stage fresh water washer, which removes latex proteins, residual soaps and curing agents. The multi-stage fresh water rinse is also unique to the Talalay process.

The mattress is transported to a two-lane dryer, which completes the curing process and removes residual moisture.

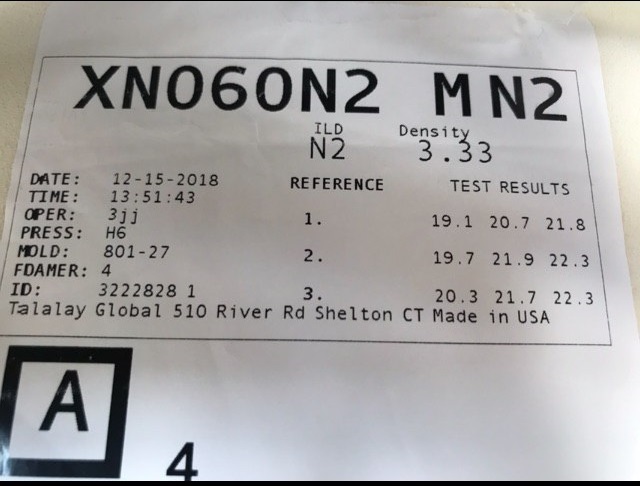

Once dry, EVERY mattress undergoes a nine-point firmness consistency test and infrared technology scan to ensure they meet our stringent quality standards.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

LOCAL STORES

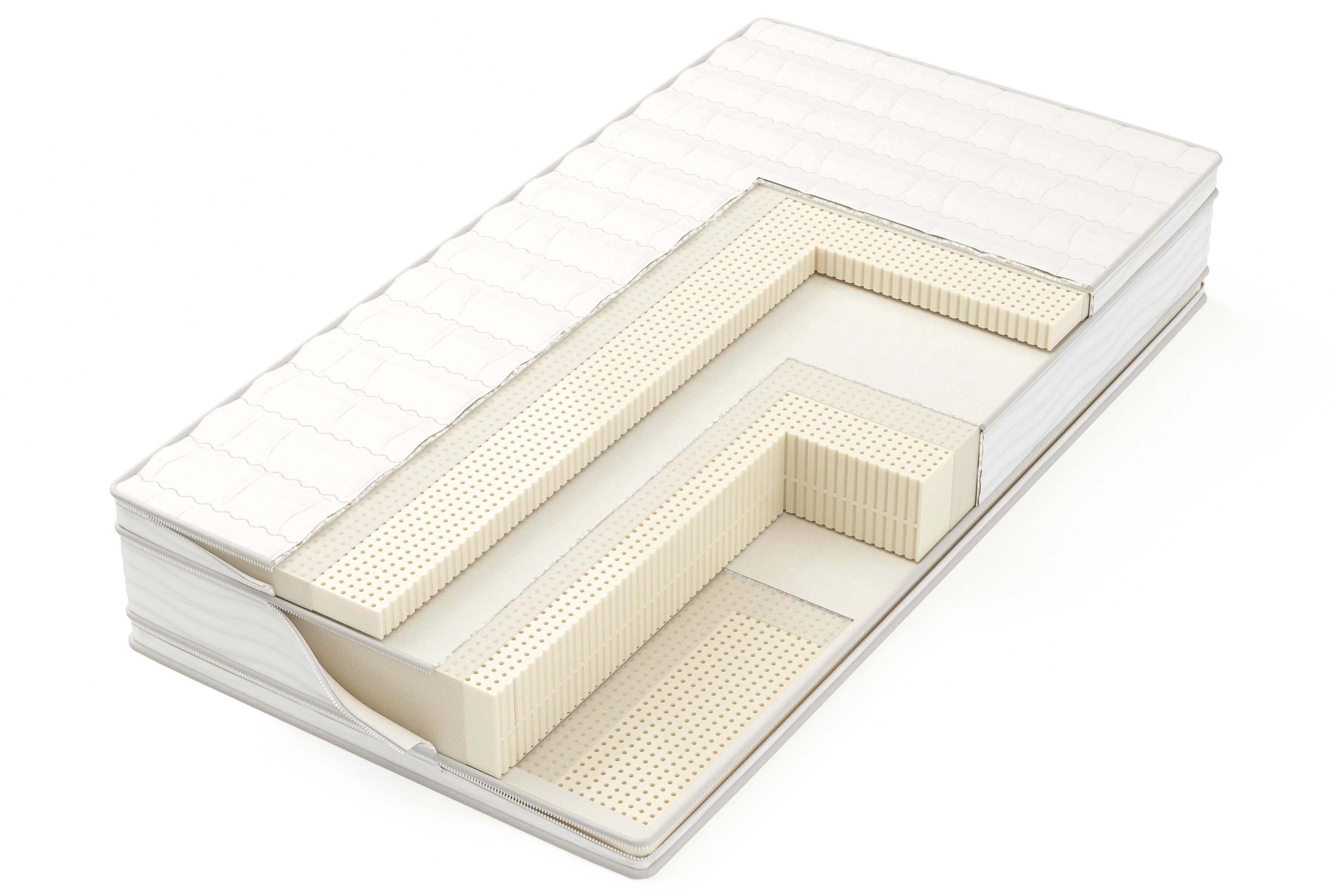

7" LATEX MATTRESS

9" LATEX MATTRESS

11" LATEX MATTRESS

%20(2).jpg)

.jpg)

HAND-MADE ONE-AT-A-TIME

.jpg)

COMPLETELY REVERSIBLE

QUILTED ON BOTH SIDES

.jpg)

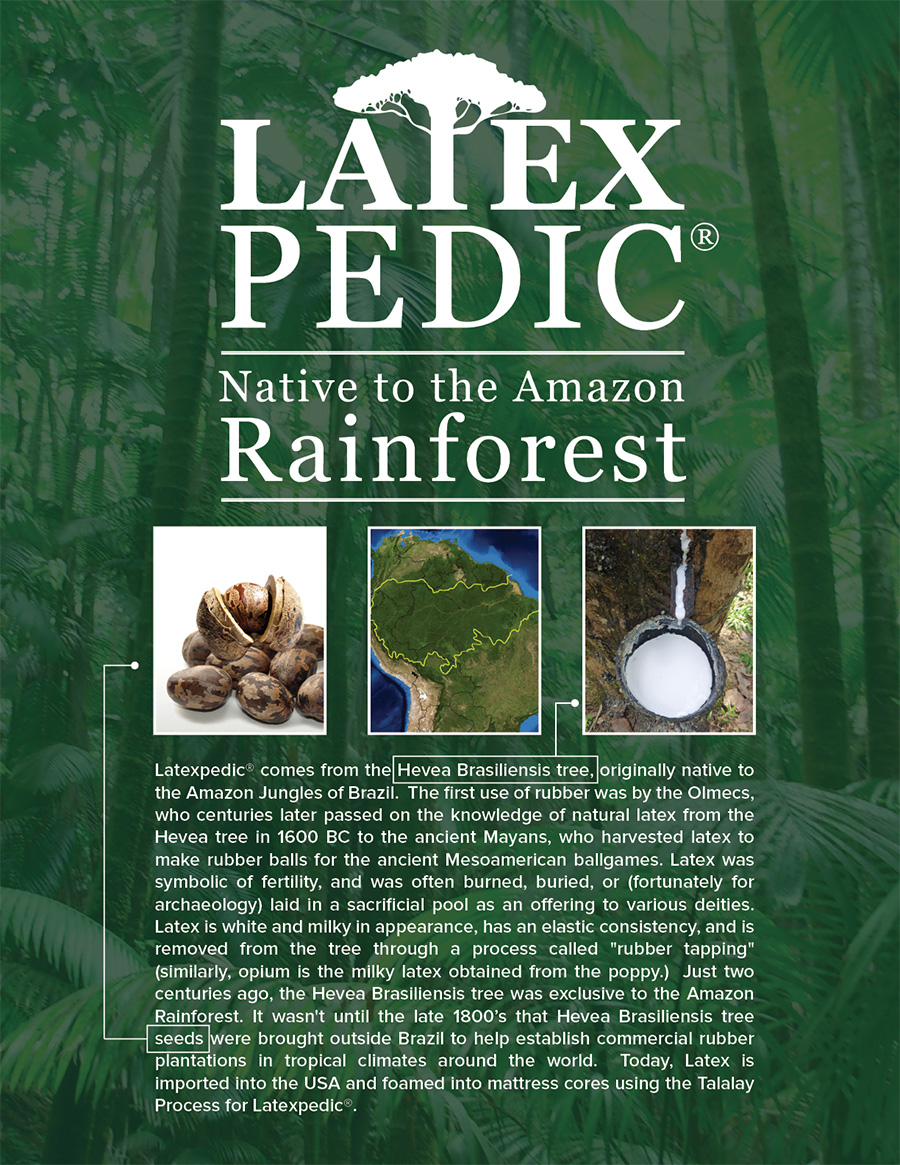

Currently, rubber is harvested mainly in the form of the latex from the rubber tree. The latex is a sticky, milky colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". The latex then is refined into rubber ready for commercial processing. In major areas, latex is allowed to coagulate in the collection cup. The coagulated lumps are collected and processed into dry forms for marketing.

The natural rubber tree takes between seven and ten years to deliver the first harvest. Harvesters make incisions across the latex vessels, just deep enough to tap the vessels without harming the tree's growth, and the latex is collected in small buckets. This process is known as rubber tapping.

%20(1).jpg)

EACH

NATURAL TALALAY CORE IS

INDIVIDUALLY RATED IN 9

SEPARATE AREAS

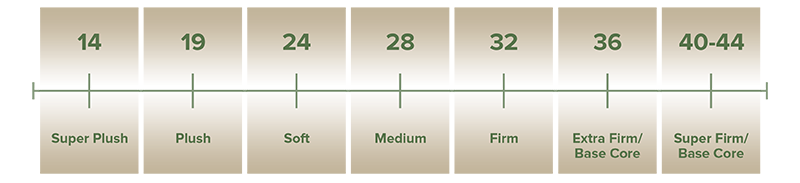

The most important consideration when you buy a new mattress is SUPPORT:

"How you feel when you wake up in the morning."

A mattress has to correctly SUPPORT your back and your posture.

Select from our 7", 9" and 11" Latex Mattress Models;

Each Model, comes is your choice of

Soft, Regular Firm, Extra Firm and Ultra Firm.

At Latexpedic Mattresses,

We take providing you with the Right SUPPORT very seriously.

(Ask about our 10-Day/$75.00 Exchange Policy.)