Even though they’re both latex, there are significant differences between

our Talalay latex and Dunlop latex. They’re manufactured using different

processes; it takes 14 hours to make a Talalay latex mattress core, but less

than one hour to make a Dunlop mattress core.

But the most important differences are benefits to you. Here are six ways

Talalay latex better serves you:

-

Breathability

Talalay latex is FOUR TIMES more breathable than Dunlop Process latex.

Why? Talalay latex is aerated and has a large cell structure. Dunlop

latex is denser latex and has a small cell structure.

-

Pressure Relief

Talalay latex is 33% more pressure relieving than Dunlop latex. Why? The

vacuum process used in making Talalay latex allows for the latex to

stretch like a rubber band so it conforms to your body. Dunlop latex is

a poured process that creates latex which is less flexible. The rubber

is more like the rubber in an eraser.

-

Durability

Talalay latex is THREE TIMES more resilient than Dunlop latex. Why? The

Talalay latex process creates a round cell structure. As the latex is

compressed, a round cell structure does not break itself down. The

Dunlop Process creates a snowflake cell structure. As you might imagine,

as you compress a snowflake cell structure, the material breaks down.

-

Consistency

Talalay latex is the same feel from top to bottom and consistent from

side to side. Dunlop process latex is softer on top and firmer on the

bottom. Why? The Talalay process uses flash freezing that prevents the

particles from settling after curing. Because there is no freezing in

the Dunlop process, particles setting in the latex during curing

creating firmness on the bottom.

-

Clean

Talalay latex can wash out more proteins (which is a primary cause of

latex allergies) than Dunlop latex. Why? The Talalay latex process uses

a five-stage fresh water rinse process.

-

Support

Talalay latex provides not only pressure relief, but also support. Why?

Talalay latex is a two dimensional material. It offers support and

pressure relief. Dunlop Process latex is a one-dimensional material. It

primarily offers pressure relief similar to foam.

What's The Difference Between Talalay Latex And Memory Foam?

Both Talalay latex and Memory Foam are marketed as the premium mattress

materials, but they are very different.

-

Talalay latex is a rubber. Memory Foam is a foam, which doesn’t

provide both support and pressure relief.

-

Talalay latex rubber is a natural material derived from the rubber

tree. Memory foam is a synthetic material and is a petroleum-based

product.

-

Talalay latex rubber has a breathable design and cell structure that

provides a temperature neutral environment. Memory foam is a dense

material, which needs heat to activate its pressure relieving

quality. It usually sleeps warmer.

-

You “sleep on” Talalay latex rubber and it has an uplifting effect.

You “sleep in” memory foam which provides a “sinking” effect.

-

Talalay latex rubber is two dimensional material. It is both

supportive by being uplifting and is also pressure relieving. Most

memory foam mattresses use memory foam in the pressure relief layer

and traditional poly foam in the support layer.

-

Talalay latex rubber is “bottomless.” Even when you lay on your

side, your body does not “bottom out” into a hard layer in the

mattress or on the foundation. Memory foam allows you to bottom out

onto what is underneath it.

-

Talalay latex rubber is a fast response material. When you move, it

immediately responds to your new position. Memory foam is a slow

response material.

-

Talalay latex rubber is hypoallergenic and does not off-gas. Memory

foam is a petroleum-based product.

-

Talalay latex rubber is extremely durable. Because it is vulcanized,

it is the most resilient material available in a mattress.

-

Talalay latex rubber is inherently antibacterial and antifungal.

How Is Talalay Latex Better For My Health?

The difference is in the chemicals. Many mattress adhesives contain a

variety of toxic chemicals. Solvent-based mattress adhesives are filled

with 48 toxic chemicals and foam has an additional 7. A Talalay latex

mattress is just that, 100% Talalay. Our beds are made with water-based adhesives

and contain 6

non-toxic chemicals (acrylate resins, diphenyl

diisocyanate, Phenol-melamine resins, Phenol-urea, Polyvinyl acetate and

waxes styrene- butadiene copolymer) and 3

natural materials (fats, hevea brasiliensis milk,

and water.)

You

spend about 1/3 of your year in bed, so it’s important to know what

you’re sleeping on.

What Health And Safety Standards Does Talalay Global Operate Under?

Our Talalay latex Products are Oeko-Tex certified,

Class I. Our Talalay is manufactured in Shelton, CT.

Oeko-Tex Association is an independent, third-party certifier. Oeko-Tex

certification is widely recognized in most of Europe. It’s awareness in

the United States is rising.

The Oeko-Tex 100 standard is concerned primarily with health and safety

of textile products.

Textiles considered for this standard are classified into four

categories listed below. Our Talalay latex is certified for Class I.

Product Classes

-

Product Class I: Products for Babies – all textile products and

materials used to manufacture such textile products for children up

to the age of 36 months (leather clothing is excepted)

-

Product Class II: Products with Direct Contact to Skin – worn

articles of which a large surface touches the skin (i.e. underwear,

shirts, pants)

-

Product Class III: Products without Direct Contact to Skin –

articles of which only a small part of their surface touches the

skin (i.e. linings, stuffings)

-

Product Class IV: Decoration Material – this may also be thought of

as housewares, as this category includes table cloths, wall

coverings, furnishing fabrics, curtains, upholstery fabrics, floor

coverings, and mattresses.

Textile products bearing the Oeko-Tex 100 certification mark are:

-

Textiles that do not contain allergenic dye-stuffs and dye stuffs

that form carcinogenic arylamines of the MAK-groups III A1 and III

A2 (see the Oeko-Tex

Website for a list of chemicals included in these

groups).

-

Textiles that had been tested for pesticides and chlorinated

phenoles.

-

Textiles that have been tested for the release of heavy metals under

artificial perspiration conditions.

-

Textiles free from formaldehyde or containing trace amounts

significantly lower than the required legal limits.

-

Textiles with a skin friendly pH.

-

Textiles free from chloro-organic carriers.

-

Textiles for garments free from biologically active finishes.

How Is Talalay Latex Environmentally Friendly?

The manufacturing process does not use solvents and does not damage the

ozone layer. Talalay Global’s Talalay latex is certified by Oeko-Tex (Europe’s

highest environmental consumer product standard) to be free of harmful

substances or chemicals.

-

Talalay latex rubber is made using an eco-friendly production

method.

The Talalay process features natural, biodegradable ingredients that

come from renewable resources and water-based raw materials: natural

latex, air and water. Latex is a rubber-based material that comes

from the tropical hevea brasiliensis tree. These trees have a

25-year productive life and they have a strong effect on the

environment as they quickly absorb carbon dioxide from the

atmosphere and help reduce greenhouse emissions.

-

Talalay latex rubber is made with energy and water conservation in

mind.

-

Energy: Talalay Global’s manufacturing automation

optimizes energy usage for the molding stage (freezing and

vulcanization portion) of the Talalay process. The state of the

art factory in Shelton, CT, USA also features energy efficient

lighting.

-

Water: Talalay Global has engineered its multi-stage

washer to minimize the amount of water consumed.

What Are The Reasons To Invest In A Talalay Latex Mattress?

-

It offers “bottomless” pressure relief for your body. Whether

you are on your back or side, you will have less pressure on more

inches of Talalay latex. Did you know when you lay on your side,

your shoulders and hips have 7 times more pressure on them than when

you lay on your back? Pressure relief is important to your muscles

and it keeps the blood flowing to your extremities so you don’t have

numb fingers, hands and arms. But more importantly, your body

responds to pressure by moving during the night which will likely

lessen the quality of your sleep.

-

It offers “uplifting” support for your body.Your body needs

support. It needs it for ideal body alignment and ideal spinal

alignment. The benefit of good support is good posture. We love the

phrase, better posture at night equals better posture during the

day. Talalay latex offers an effect that is not found with

traditional bedding materials. Talalay latex is uplifting and it is

also pressure relieving. All other materials in a mattress are

either one or the other, but not both. Most people think they need a

firm bed, but that is only partially true. They need a bed with

strong support, but they also need a bed that offers pressure relief

on top of that. Firm on the bottom and soft on top is probably a

more ideal formula.

-

It offers a “resilient” natural rubber construction.Most

people want a mattress to last a long time. It is a big investment.

Simply put, you can buy an $1,000 mattress three times over the

years or you can buy one $3,000 mattress and have it last 15 years.

Talalay latex is incredibly resilient. The easiest way to understand

that Talalay latex lasts longer is to understand that Talalay latex

is a rubber not a poly foam. Rubber is more resilient. It’s the

nature of the material.

-

It is Healthy By Design

-

It is naturally breathable so it dissipates body heat

-

It is naturally mold and mildew resistant so it may help your

sneezing and wheezing

-

It is naturally dust mite resistant if you have asthma

-

It is inherently antibacterial and antifungal

-

It is naturally hypoallergenic so it doesn’t off-gas

-

It is naturally motion isolating so you will feel less of your

partners movement

Quality

Talalay vs. Dunlop

Not all latex is created equal. Talalay and Dunlop are the two processes

used in mattress production. The Dunlop process was developed in 1929 and

was the first method used to produce latex material for bedding.

As technology progressed, the Talalay process was developed by the Talalay

family during World War II. The Talalay process is significantly more

complex and costly, but produces softer, more buoyant and luxurious finished

products.

So why is there such a difference? The Talalay process takes four times

longer than Dunlop with two additional process steps—vacuum and flash

freezing—which improve the consistency, quality and feel of the finished

latex.

The vacuum evenly distributes the latex throughout the mold, allowing us to

create precise and varied feels in the finished Talalay latex. A mattress is

made more firm or plush based on how much latex is poured into the mold.

With the Dunlop process there is little ability to vary the feel of the

finished product because the liquid latex is poured onto a conveyor belt

resulting in a dense piece of latex every time. The only way to soften the

feel of Dunlop latex is to add “fillers” into the liquid latex formula,

which can result in solid latex that is flaky and breaks down quickly.

The flash freezing step gives Talalay its consistent feel. Liquid latex is a

suspension of rubber particles in water, like a shaken snow globe. Flash

freezing prevents the latex particles from settling to the bottom while

gelling into a solid product. This means that the resulting piece of solid

Talalay latex has the same consistent feel from top to bottom, and side to

side. The Dunlop process doesn’t utilize a freeze step. Therefore, the

rubber particles settle to the bottom while the liquid latex is gelling into

a solid form, resulting in a variation of feel from top to bottom.

Think of Talalay latex like a chocolate soufflé; although the process is

long, the end product is a buoyant, airy, complex delight. Dunlop latex is

more like a pound cake; tasty, but dense and flat in comparison.

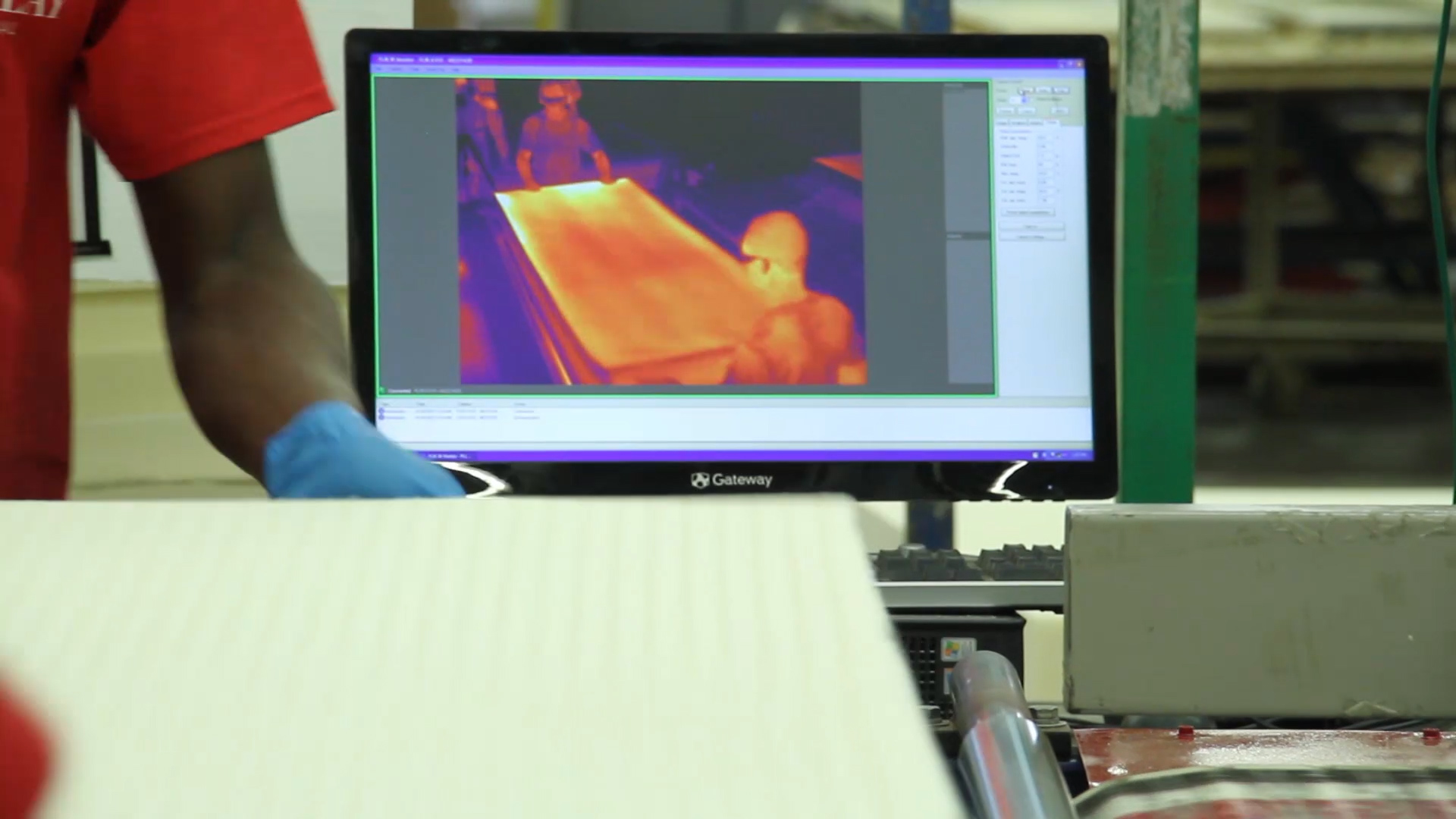

Quality Testing

Only the best pass our tests. Every single bed goes through compression and

impact tests to ensure durability and consistency.

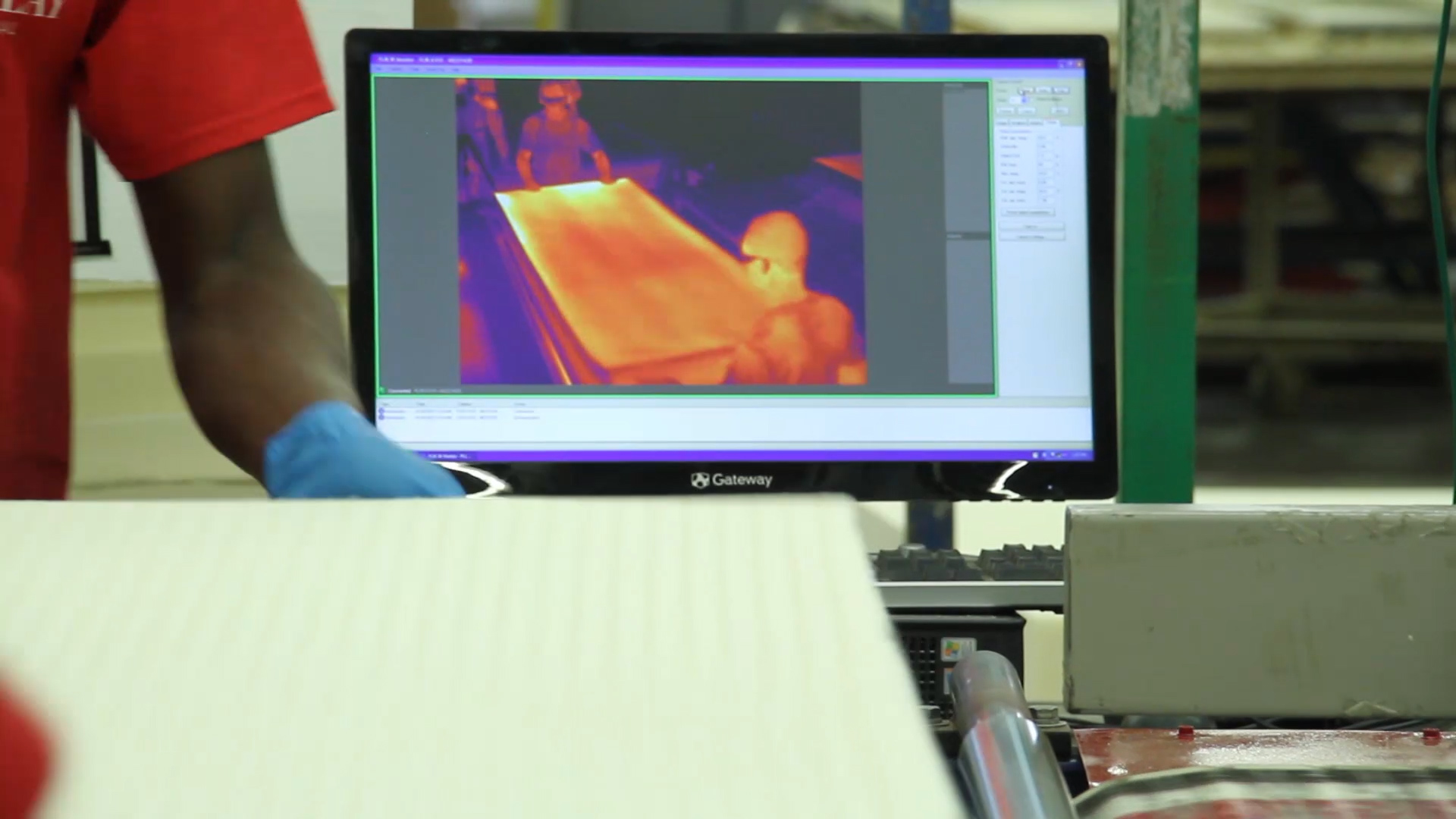

Compression Test

This test simulates the effect of body impressions on the latex after a

person lies on the bed for extended periods of time. Latex mattress samples

are compressed to 50% of their original thickness for 22 hours at 158 ° F.

When removed, the percent loss in thickness is measured. The greater the

loss thickness, the more likely the bed will take a body impression over

time—which leaves you sleeping in a hole.

|

|

Talalay Global Latex |

Imported European Talalay Latex |

Dunlop Latex |

|

% Compressed |

3.3% |

5.7% |

11% |

|

Comparison |

— |

73% more compressed |

223% more compressed |

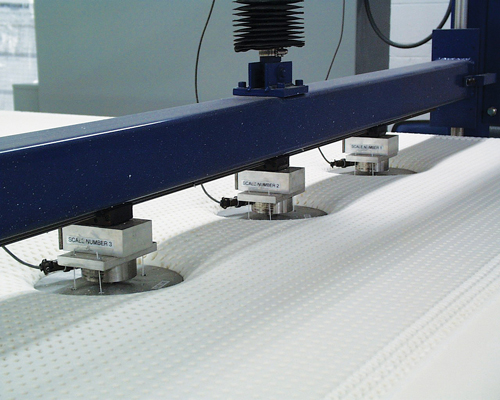

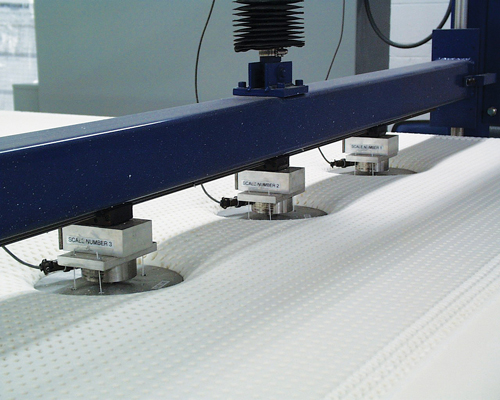

Impact Test

The impact test measures Indentation Load Deflection (ILD), a measure of

firmness. The mattress core is ILD tested and then placed into a machine

where a weight is dropped on the latex repeatedly for 24 hours. The product

is then removed from the machine and allowed to recover for 24 hours. ILD is

measured again. The greater the loss in firmness from first measurement to

the second means the latex is more likely to breakdown over time. To ensure

we produce the most consistent feeling products, Talalay Global ILD tests

nine locations on every mattress core. We are the only manufacturer in the

industry to do so.

|

|

Talalay Global Latex |

Imported European Talalay Latex |

Dunlop Latex |

|

% Loss of Firmness |

6% |

16%Phoenix-Mattresses.html |

18% |

|

Comparison |

— |

167% more loss |

200% more loss |

.jpg) |

907 Hollywood

Way, (1/2 bl. S. of Magnolia Bl., Burbank CA 800-727-1954

1035 E. Camelback Rd., (1 mi. E. of Central

Ave.) Phoenix 800-733-1818

Open Mon-Sat 10-5, Sun 12-4

SERVING ALL AREAS 800-733-1818

|

"Phoenix Latex Mattresses"

We serve all of Phoenix with

our Factory Direct Latex Mattress Showroom 800-733-1818

.jpg)